LCP High-Frequency Materials provide superior signal integrity, exceptional thermal stability, and optimized dielectric properties. Designed for 5G communications, RF applications, and high-speed circuitry, they ensure reliable performance, low-loss transmission, and enhanced durability.

Product Overview

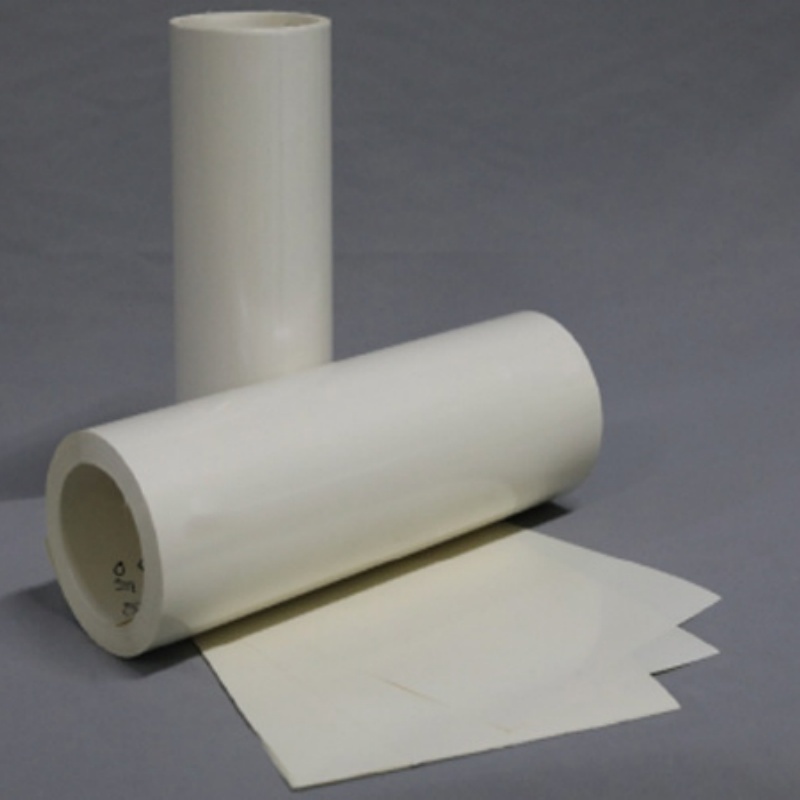

LCP (Liquid Crystal Polymer) material is a high-performance polymer with extremely low thermal expansion coefficients and low tangent loss, making it especially suitable for high-frequency and millimeter-wave applications. It offers outstanding electrical and thermal stability and maintains a constant dielectric constant even at high frequencies. LCP materials are commonly used in flexible circuit boards (FPC), particularly in communications, consumer electronics, and vehicle networking fields, showing great potential in modern technology.

Product Features

- Low Dielectric Constant:Maintains a stable dielectric constant under high-frequency conditions, making it ideal for high-frequency signal transmission.

- Low Tangent Loss:Extremely low tangent loss optimizes signal quality, making it suitable for millimeter-wave applications.

- Minimal Thermal Expansion:Ideal for high-frequency packaging materials, reducing the impact of thermal stress.

- Flexible Design:Can be processed into flexible circuit boards (FPC), enhancing system integration.

- High-Speed Transmission:Supports rapid transmission of high-frequency signals, meeting modern high-speed communication demands.

Applications

- Communication Equipment:Used in base station equipment to optimize signal transmission and communication efficiency.

- Consumer Electronics:Applied in antennas, camera modules, and other electronic products to improve product performance and stability.

- Vehicle Networking (V2X):Used in control systems, sensors, and vehicle communication devices to enhance vehicle communication quality and safety.

- Smart Home:Applied in smart home control systems to enhance the stability and responsiveness of home automation systems.

- Autonomous Driving & Wearable Devices:Used in smartphones, autonomous systems, and wearable devices to support high-speed communication and precise positioning capabilities.

| Item | Unit | Testing Method |

| Tensile Strength | MPa | HD-B604B-S |

| Elongation at Break | - | HD-B604B-S |

| Tensile Modulus | MPa | HD-B604B-S |

| Coefficient of Thermal Expansion | ppm/°C | TATMA450 30~250°C |

| Melting Point | - | TA DSC 25 |

| Surface Resistivity | Ω-cm | GB/T31838.2-2019 |

| Volume Resistivity | Ω-cm | GB/T31838.2-2019 |

| Water Absorption | - | Bready method (25°C, 50% R.H.) |

| Dielectric Constant (Dk) | - | MS46122B Frequency 28GHz |

| Dissipation Factor | - | - |

new material

new material