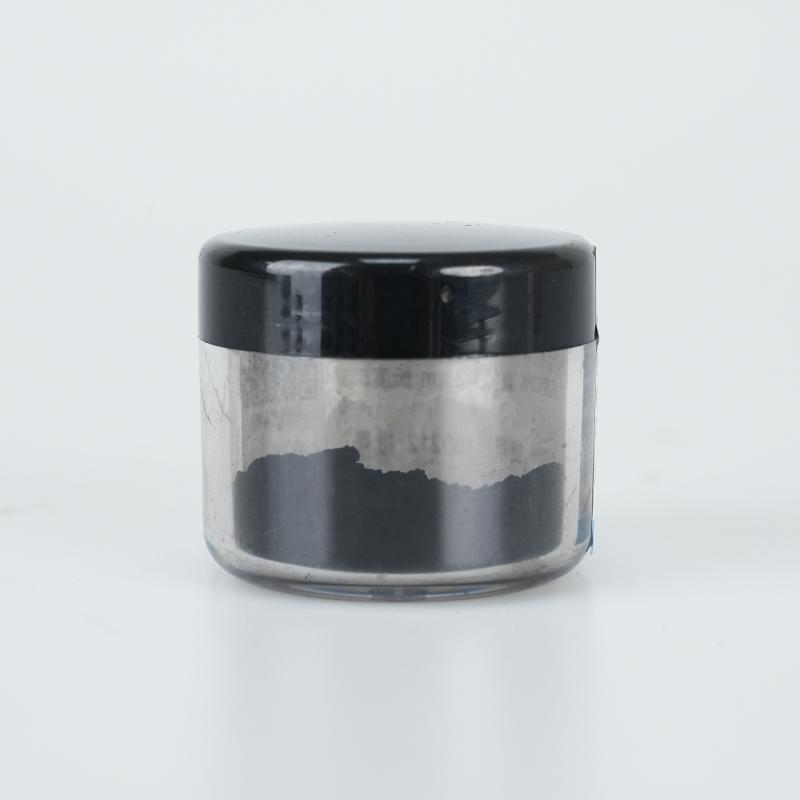

Dispersible nano diamond offers optimized thermal conductivity, superior mechanical reinforcement, and enhanced surface stability. Designed for high-performance coatings, lubrication, and electronic applications, it ensures efficient heat dissipation, extended durability, and high adaptability.

Product Overview

Dispersible nano diamonds are a special type of diamond synthesized using the explosive method, exhibiting nanoscale size effects. The particles are typically near-spherical or polyhedral in shape. The surface of nano diamonds is rich in functional groups such as carboxyl, hydroxyl, and others, which enhance their chemical reactivity and dispersion in water. These features allow for chemical modification of the surface, making nano diamonds suitable for a wide range of applications, including biomedical, lubricating materials, and wear-resistant materials.

Key Features

- Rich Surface Functional Groups:Nano diamonds have a variety of functional groups on their surfaces, which enhances their chemical reactivity and dispersion stability, allowing them to interact with different molecules.

- Thermal Conductivity:As an excellent thermal conductor, nano diamonds are ideal for applications that require efficient heat transfer.

- Low Friction Coefficient:The low friction coefficient of nano diamond surfaces makes them ideal as lubricants, effectively reducing friction and fuel loss at machine part connections.

- Biocompatibility:Excellent biocompatibility allows for extensive use in the medical field, such as in drug delivery and antibody drug manufacturing.

Applications

- Enhance Metal Coating Wear Resistance:Adding nano diamond powder during electroplating can refine metal grain size, improving the microhardness of metals.

- Metal Lubricants:Nano diamonds' low friction characteristics make them suitable for use as metal lubricants, reducing friction and wear, thus improving machine efficiency.

- New Wear-resistant Materials:When mixed with copper-zinc, copper-tin powders, and sintered, nano diamonds create wear-resistant materials widely used in internal combustion engine liners, transmission machinery bushings, and more, offering high scratch resistance and wear resistance.

- Biomedical Field:In oncology, cardiology, and vascular diseases, nano diamonds exhibit high adsorption capability and biocompatibility, making them suitable as drug carriers or antigen carriers.

- Thermal Conductive Materials:Nano diamonds can be used as thermal conductive materials in electronic devices and other high-heat applications for efficient thermal management.

- Chemical Vapor Deposition (CVD) Diamond Films:Nano diamond powders can be used in the production of CVD diamond films, promoting the growth of diamond microcrystalline layers and enhancing film nucleation density.

new material

new material