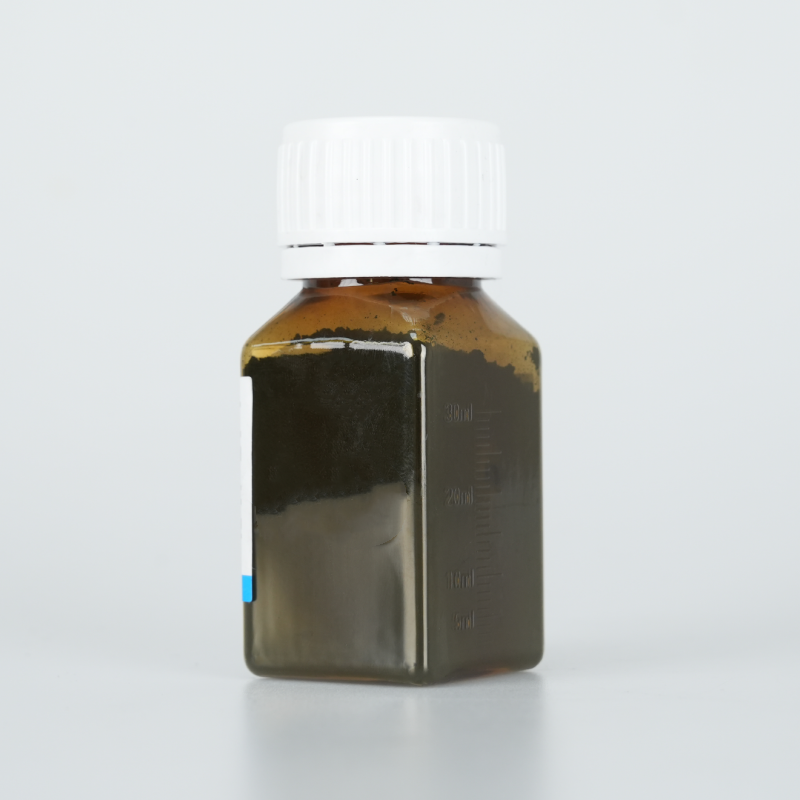

Oleic acid-modified Fe₃O₄ magnetic nanoparticles provide optimized hydrophobicity, superior colloidal stability, and enhanced magnetic responsiveness. Designed for advanced biomedical and industrial applications, they ensure efficient dispersion, extended lifespan, and high adaptability.

Product Overview

Oleic acid-modified Fe₃O₄ magnetic nanoparticles are synthesized via a high-temperature pyrolysis method, where oleic acid is used as a surfactant in the solution containing iron precursors. Oleic acid not only helps control the growth of the nanoparticles but also forms a stable coating on the surface, which imparts excellent magnetic properties and uniform size distribution to the nanoparticles. This modification allows the nanoparticles to disperse in oil phases, making them suitable for applications in magnetic resonance imaging (MRI), sensors, and nanoemulsions.

Key Features

- Oil Solubility: These nanoparticles are oil-soluble and can be dispersed in organic solvents such as cyclohexane, chloroform, and tetrahydrofuran, making them suitable for various solvent systems.

- Synthesis via High-Temperature Pyrolysis: The high-temperature pyrolysis method used in the synthesis ensures that the oleic acid-modified Fe₃O₄ nanoparticles possess strong magnetic properties and uniform size distribution.

- Stability: The oleic acid modification enhances the stability of the nanoparticles, ensuring their long-term performance across various applications.

- Versatile Specifications: Various sizes of nanoparticles are available to meet the requirements of different applications.

Applications

- MRI Contrast Agent: Due to their superparamagnetism, these nanoparticles can be used as contrast agents in MRI, enhancing image contrast for clearer observation of tissues and organs.

- Biosensors and Detection: In biosensors, Fe₃O₄ nanoparticles can function as signal converters or enhancers, improving detection sensitivity and selectivity.

- Water-in-Oil Nanoemulsions: Oleic acid-modified Fe₃O₄ nanoparticles can be dispersed in organic solvents for incorporation into water-in-oil nanoemulsions, with applications in pharmaceuticals and cosmetics.

| Technical Parameter | Description |

| Form | Solid or solution |

| Preparation Method | High-temperature pyrolysis method |

| Saturation Magnetization | ~60 emu/g Fe |

| Dispersibility | Oil-soluble, can be dispersed in solvents like chloroform, n-hexane |

| Features | Stronger magnetism and more uniform size compared to the co-precipitation method. |

| Notes | The Fe concentration in the solution is 1 mg/mL, while the concentration in the powder is unknown. |

| The TEM image is obtained from the solution; larger particles may appear in the powder test. If morphology observation is required, it is recommended to purchase the solution. | |

| Particles larger than 30nm can be separated directly by magnets, while particles smaller than 30nm are recommended to be separated by magnetic separation columns. | |

| The dispersibility of re-dispersed powder is worse than the dispersion liquid. For better dispersion, please choose the dispersion liquid. |

new material

new material