Silicone oil dispersant enhances dispersion stability, optimizes surface compatibility, and ensures superior fluid uniformity. Designed for advanced applications, it improves solubility, extends functionality, and enhances formulation efficiency in diverse systems.

Product Overview

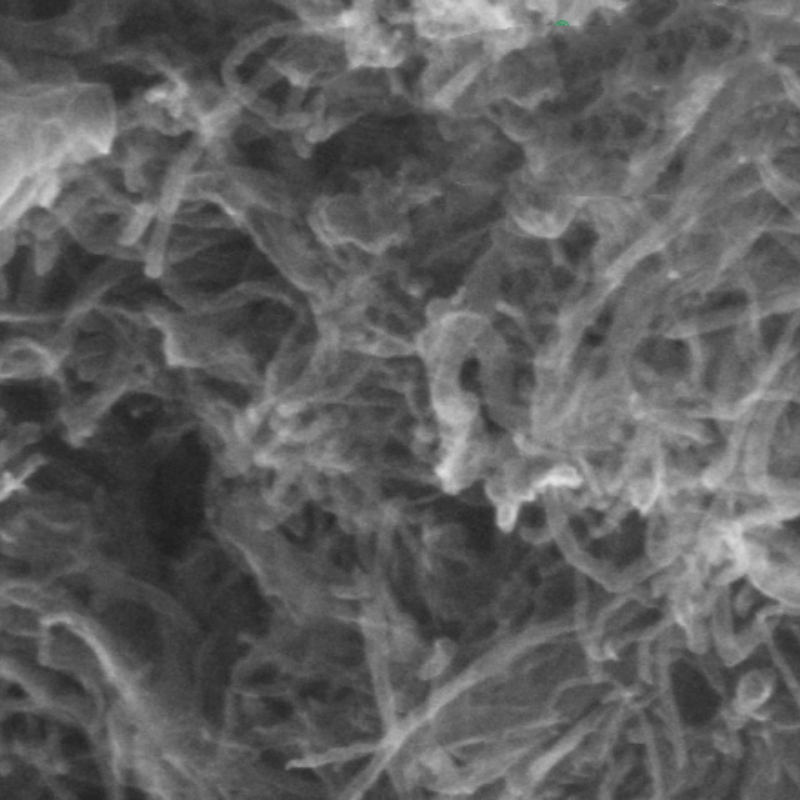

The Silicone Oil Dispersant is specifically designed to improve the dispersion of carbon materials (such as carbon nanotubes and graphene) in polymer matrices. Due to their high specific surface area and surface energy, carbon materials tend to agglomerate, making uniform dispersion challenging. This dispersant effectively reduces surface tension, enhancing the wetting and dispersion of carbon materials in silicone polymer systems, ensuring uniform distribution and improved performance.

Key Features

- Reduced Surface Tension:Facilitates better wetting and encapsulation of carbon materials with the polymer matrix.

- Steric Hindrance Effect:Forms a protective layer through adsorption, preventing agglomeration between carbon material particles.

- Charge Stabilization:Charged dispersants maintain particle dispersion through electrostatic repulsion.

Applications

Silicone oil dispersants are widely used in any silicone polymer systems for the wetting and dispersion of fillers and pigments. They are particularly useful in improving flow properties, leveling, adhesion, and flexibility. It is recommended to add the dispersant during the dispersion stage of pigments and fillers, with a typical usage rate of 0.2-2% of the total formulation.

| Technical Parameter | Value |

| Appearance | Yellow transparent viscous liquid |

| Composition | Modified organic copolymer |

new material

new material