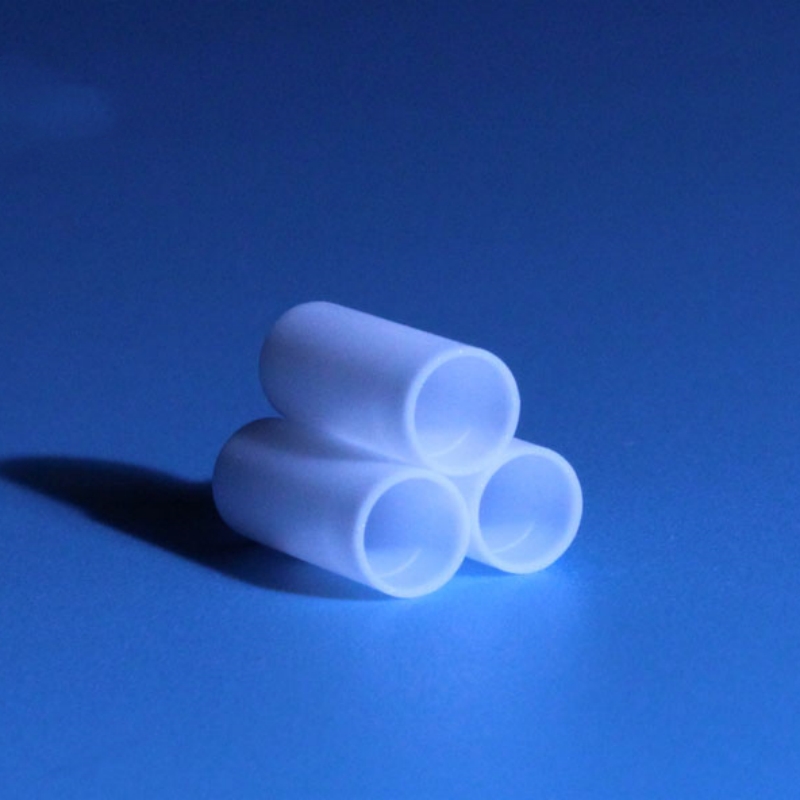

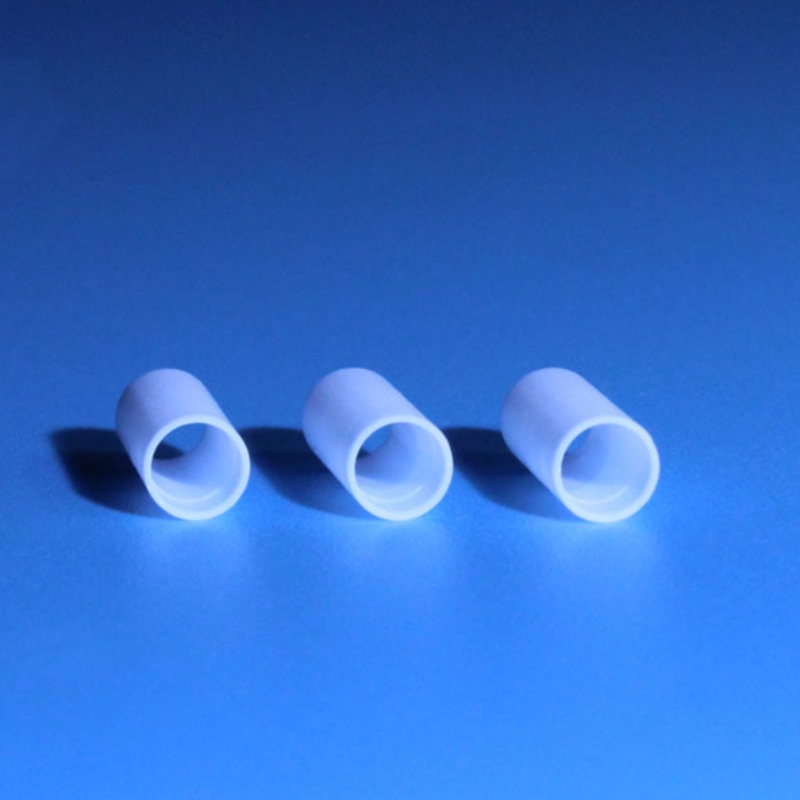

Machinable ceramic tubes provide precise structural integrity, optimized thermal resistance, and superior dielectric insulation. Designed for industrial applications, they offer enhanced machinability, extended lifespan, and reliable high-temperature performance.

Product Overview:

The machinable ceramic tube is made from machinable ceramic materials that combine the excellent properties of fluorinated mica and borosilicate glass. This tube features zero porosity and outgassing, making it ideal for high-temperature and ultra-high vacuum environments. With its low thermal conductivity and excellent electrical insulation properties, this material can maintain stable performance in high-temperature and high-pressure conditions. Its exceptional machinability allows it to be processed into complex shapes using conventional metalworking tools, making it suitable for a wide range of high-tech industrial and medical applications.

Product Features:

- Superior Vacuum Performance:Zero porosity and zero outgassing make it ideal for ultra-high vacuum environments, ensuring no outgassing risks.

- High-Temperature Stability:Continuous use temperature up to 800°C, with peak temperatures reaching 1000°C, ensuring stable operation in extreme conditions.

- Good Thermal Expansion Compatibility:The coefficient of thermal expansion (CTE) matches that of most metals and sealing glasses, making it suitable for sealing and supporting precision equipment.

- Low Thermal Conductivity and Electrical Insulation:Excellent electrical insulation properties and low thermal conductivity, making it ideal for applications such as electrode supports and burner blocks in high-temperature, electrically intensive operations.

- Precision Machinability:Can be machined into complex shapes with high precision using traditional metalworking tools like milling, turning, and drilling.

- Dimensional Stability:Macor material maintains dimensional stability under high radiation environments, making it suitable for use as a reference material in precision measurements.

- High Strength and Durability:Retains high mechanical strength under high-temperature and high-pressure conditions, ensuring long-term reliability.

Applications:

- High-Temperature and High-Pressure Applications:Ideal for support and sealing materials in environments such as welding nozzles, electrode supports, and burner components.

- Ultra-High Vacuum Environments:Widely used in ultra-high vacuum applications such as particle accelerators, optical equipment, and semiconductor manufacturing accessories.

- Medical Devices:Used in medical devices to manufacture inert and highly precise components, such as surgical tools and equipment supports.

- Precision Instruments:Applied in precision measurement and testing equipment as a stable, high-temperature reference material.

- Welding and Cutting Equipment:Used in welding equipment nozzles, torch tips, and other components, as its non-wetting properties prevent molten particles from adhering, ensuring nozzle efficiency.

- Electronics and Optics:Used as a stable and reliable support and insulation material in electronic components and optical equipment.

new material

new material