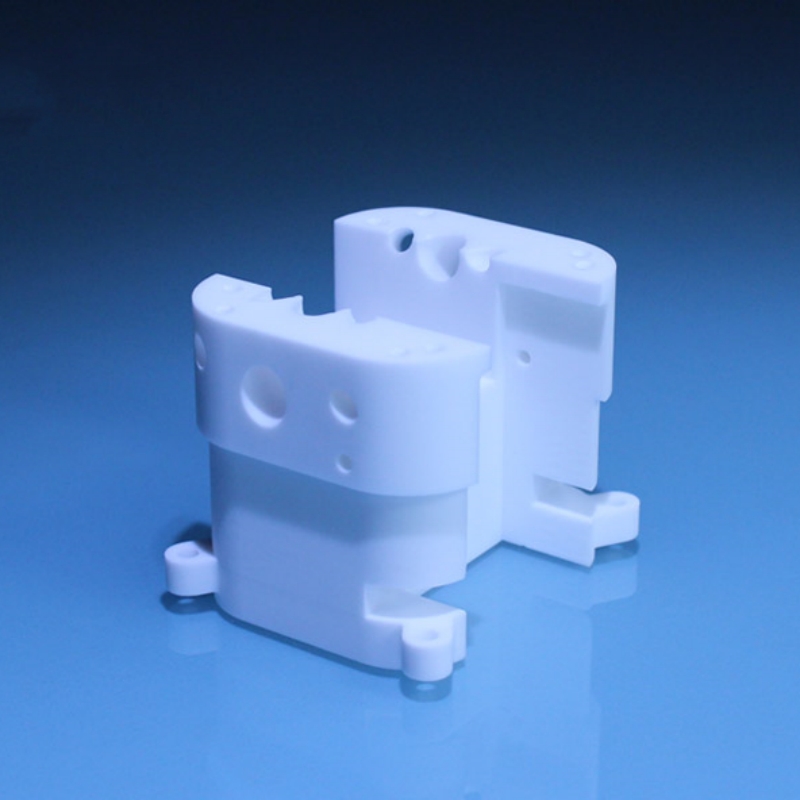

Machinable ceramic ultra-high vacuum lens supports, made from Macor, ensure exceptional thermal stability, optimized dielectric insulation, and precise structural integrity. Designed for vacuum applications, they provide reliable mechanical support, extended lifespan, and superior machinability.

Product Overview

Machinable Ceramic Ultra-High Vacuum Lens Supports are made from machinable ceramic material, combined with the excellent properties of fluorine mica and borosilicate glass. This material has zero porosity and zero outgassing rate, making it particularly suitable for applications in ultra-high vacuum environments. Macor not only maintains stability in extreme temperatures (up to 1000°C) and high-pressure conditions but also offers excellent thermal expansion compatibility, making it ideal for use in precision environments. Through multi-axis CNC machining, that material can be quickly shaped into complex designs, making it widely applicable in advanced research and industrial fields.

Features

- Ultra-High Vacuum Performance: Exhibits zero porosity and zero outgassing rate, stable in ultra-high vacuum environments down to 10^-10 Pa.

- High-Temperature Stability: Suitable for continuous use at temperatures up to 800°C, with peak temperatures reaching up to 1000°C, designed for high-temperature operations.

- Good Thermal Expansion Match: The thermal expansion coefficient matches most metals and sealing glasses, preventing material deformation due to temperature differences.

- Machinability: Can be easily machined using conventional metalworking tools (e.g., milling, drilling, etc.) to accommodate various complex shapes and design needs.

- High-Precision Machining: Offers high machining precision with roughness as low as Ra 0.8 µm, and can be further polished to Ra 0.05 µm, meeting strict precision requirements.

- Electrical and Thermal Management Performance: Excellent electrical insulation and thermal conductivity, suitable for supporting precision equipment and sensitive components.

- Mechanical Strength and Stability: Maintains mechanical strength and stability under high-pressure and harsh environmental conditions, ensuring long-term reliability.

Applications

- Ultra-High Vacuum Applications: Widely used in advanced research, experimental equipment, and particle accelerators for lens supports and precision components in ultra-high vacuum environments.

- High-Temperature and High-Pressure Environments: Suitable for high-temperature and high-pressure equipment in aerospace, semiconductor manufacturing, materials science, and more.

- Electronics and Optical Equipment: Used in high-precision optical systems, electron microscopes, fiber optic sensors, and other high-end electronic devices, ensuring efficient operation and stability.

- High-Precision Measurement and Testing: Provides strong and reliable support in experimental and testing equipment that requires high precision and stability.

- Vacuum Sealing and Packaging: Used as effective support and isolation materials in vacuum sealing systems, ensuring device sealing integrity and durability.

new material

new material