Self-sharpening diamond series is an advanced synthetic diamond material engineered for continuous cutting efficiency, extended durability, and superior wear resistance. Designed with an optimized microstructure, these diamonds exhibit controlled fracturing properties that allow for automatic sharpening during use, ensuring consistently high performance in precision machining, grinding, and high-speed cutting applications. Widely used in aerospace components, automotive tooling, semiconductor manufacturing, and heavy-duty industrial processes, self-sharpening diamond materials enhance productivity and minimize tool wear over time.

Product Overview

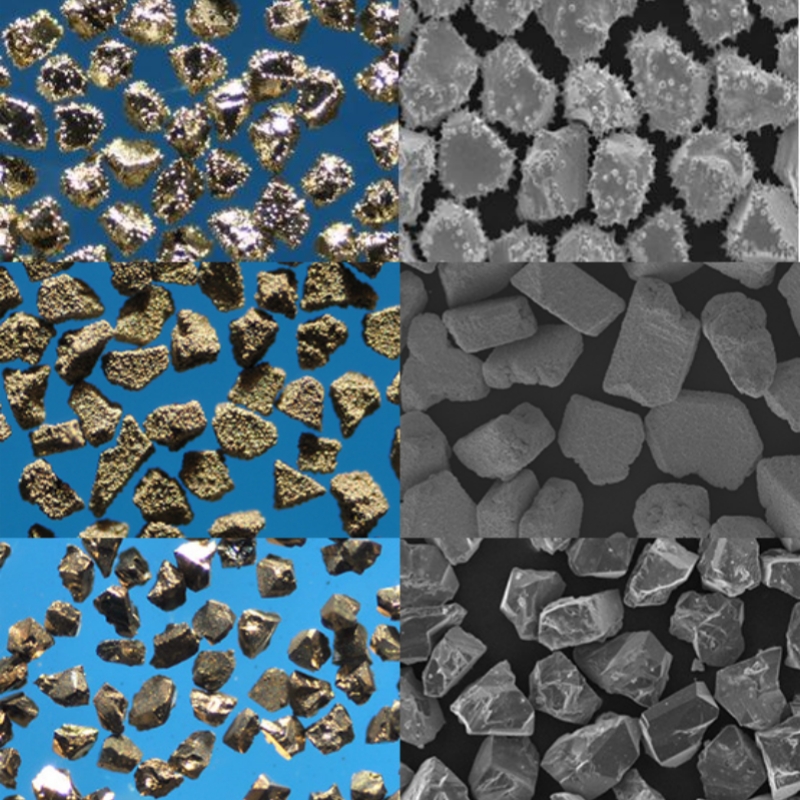

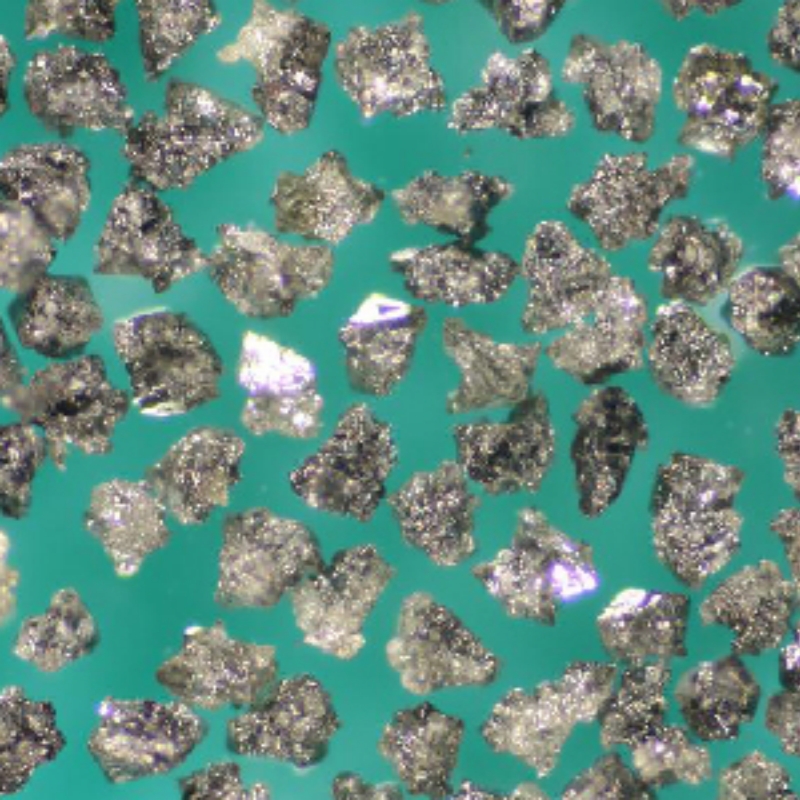

The Self-Sharpening Diamond Series utilizes boron-doped polycrystalline diamond abrasives, primarily used in resin bond diamond wheels. The diamond particles in this series have irregular shapes and rough concave surfaces, allowing them to maintain continuous self-sharpening during the grinding process. This results in high grinding efficiency, long service life, and excellent surface finish. Under grinding force, the diamond particles easily fracture along subgrain boundaries to form sharp cutting edges, which not only increase the abrasive utilization but also improve the workpiece surface quality.

Features

- Self-Sharpening: During the grinding process, diamond particles continuously form sharp cutting edges, maintaining high grinding efficiency.

- High Surface Finish: Uniform brittleness ensures no scratches or burn marks on the processed surface, resulting in excellent surface quality.

- Long Service Life: The rough surface and concave angles increase the bond strength and service life of the abrasive.

- Low Internal Stress: The even distribution of stress on the processed workpiece surface greatly enhances its service life.

- High Grinding Efficiency: Provides high grinding performance and low grinding resistance, making it suitable for hard material processing.

Applications

- Hard Alloy Processing: Used for cutting, grinding tools, and wire-drawing dies.

- Ceramic Material Grinding: Suitable for precision grinding of silicon nitride, porcelain, alumina, silicon carbide, glass, and other ceramic materials.

- High-Precision Grinding: Exhibits extremely high grinding efficiency and precision in applications with high wheel life and profile retention requirements.

- Heavy-Duty Grinding: Ideal for heavy-duty grinding of materials like stone, granite, ceramic tiles, marble, and glass.

- Resin Bond Diamond Wheels: Widely used in various dry and wet grinding fields, providing sustained high-efficiency grinding.

new material

new material