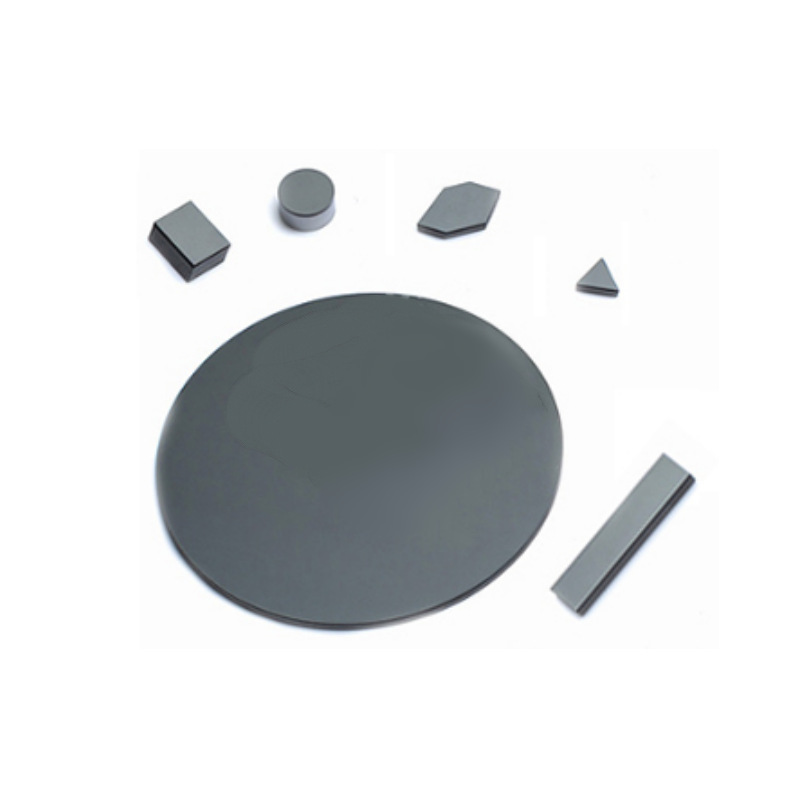

PCD diamond blanks are high-performance polycrystalline diamond (PCD) materials designed for industrial applications requiring exceptional hardness, wear resistance, and precision cutting capabilities. Manufactured through high-pressure, high-temperature (HPHT) sintering processes, these blanks exhibit uniform grain structures, superior edge retention, and optimized toughness. Widely used in precision machining, aerospace components, automotive tooling, and metalworking, PCD diamond blanks ensure extended tool life and enhanced operational stability in demanding environments.

Product Overview

PCD (Polycrystalline Diamond) composite blanks are manufactured using advanced technology, offering excellent microstructure control and reduced internal impurities, ensuring high quality and stability. These blanks effectively balance toughness and wear resistance during use, providing exceptional performance in a wide range of precision machining applications.

Features

- Excellent Surface Processing Capability: PCD composite blanks provide outstanding surface finish, especially in complex tool machining.

- Exceptional Wear Resistance: High diamond content gives the blanks strong wear resistance, making them suitable for high-load and high-wear tasks.

- Good Toughness and Impact Resistance: Balances toughness and wear resistance, ensuring stable performance in high-intensity applications.

- Thermal Stability: Excellent thermal stability, capable of handling high-temperature processing requirements.

Applications

- Metal Machining: Ideal for precision machining of metals such as aluminum, aluminum alloys, copper, copper alloys, and bronze, especially in high-speed cutting operations.

- Non-Metal Material Machining: Widely used for precision machining of non-metal materials like plastics, carbon fiber composites, circuit boards, and graphite.

- High-Wear Cutting: Suitable for cutting tasks requiring high wear resistance, such as grooving, slotting, and drilling hard alloys.

- Woodworking and Ceramic Machining: Provides excellent edge strength and stability for machining wood and ceramic products.

- High-Speed Automated Machining Equipment: Designed for high-speed automated machining equipment, offering consistent surface quality.

| Grade | Particle Size | Binder | Characteristics | Applications |

| PCD510 | 10μm | Metal | General-purpose PCD grade, combining impact resistance and high wear resistance | Wood, graphite, stone, etc. |

| PCD512W | 10μm | Metal | General-purpose PCD grade, excellent EDM performance, combining wear resistance and impact resistance | Wood, plastic sheet, graphite, ceramics, etc. |

| PCD605 | 5μm | Metal | Excellent EDM processing, impact resistance, machinability, and wear resistance | Low-silicon aluminum alloys, wood, plastic, etc. |

| PCD612 | 10μm | Metal | General-purpose PCD grade, combining impact resistance and higher wear resistance | Medium to high-silicon aluminum alloys, metal matrix composites, ceramics, acrylic, graphite, etc. |

| PCD632 | 2-30μm | Metal | Mixed particle size for composite pieces with higher wear resistance, thermal stability, and good impact resistance | High-silicon aluminum alloys, composite plastics, bimetallic materials, metal matrix composites, ceramics, etc. |

new material

new material