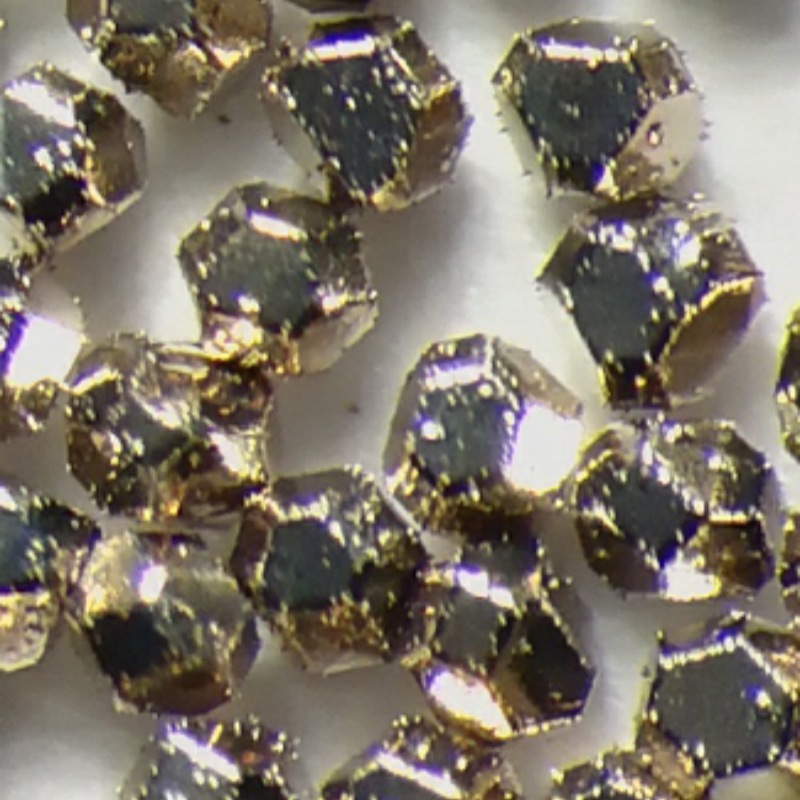

Electrodeposited nickel diamond products (N30) are high-performance composite materials designed for extreme hardness, wear resistance, and enhanced thermal stability. Manufactured using advanced electroplating techniques, these products feature a uniform distribution of synthetic diamond particles within a durable nickel matrix, ensuring optimal cutting efficiency and extended tool life. N30-grade materials are widely used in precision machining, abrasive grinding, aerospace tooling, and high-performance industrial applications requiring superior durability under demanding conditions.

Product Overview

Electrodeposited nickel diamond products (N30) are created by an electrodeposition process that forms a uniform nickel layer on the surface of diamond particles, enhancing the bond strength between the diamond particles and the tool matrix. This nickel layer effectively prevents thermal and chemical damage to the diamond tool during the forming and usage process. It also significantly improves the stability of diamond particles and the overall durability of the tool. This nickel coating is particularly suitable for high-temperature applications, offering more stable and long-lasting performance.

Features

- Uniform and Complete Electrodeposited Nickel Layer: The nickel coating is uniform and dense, enhancing the bond strength between diamond particles and the tool matrix.

- Effective Prevention of Thermal and Chemical Damage: The nickel layer resists thermal damage and chemical corrosion, extending the tool's lifespan.

- High Temperature Stability: Especially suitable for use in high-temperature environments, ensuring long-term stability of the tool.

- Improved Particle Holding Strength: Enhances the bond between diamond particles and the matrix, improving the tool’s efficiency and stability.

Applications

- Metal Bonded Tools: Suitable for diamond tools with metal binders, providing stability and wear resistance under high temperatures.

- Ceramic Bonded Tools: Especially suitable for ceramic bonded diamond tools, demonstrating excellent performance at elevated temperatures.

- Resin Bonded Tools: Suitable for diamond tools with resin binders in high-temperature environments, improving tool stability and durability.

- High-Temperature Conditions: Ideal for diamond tools used under high-temperature molding and operating conditions, ensuring stable and long-lasting performance.

new material

new material