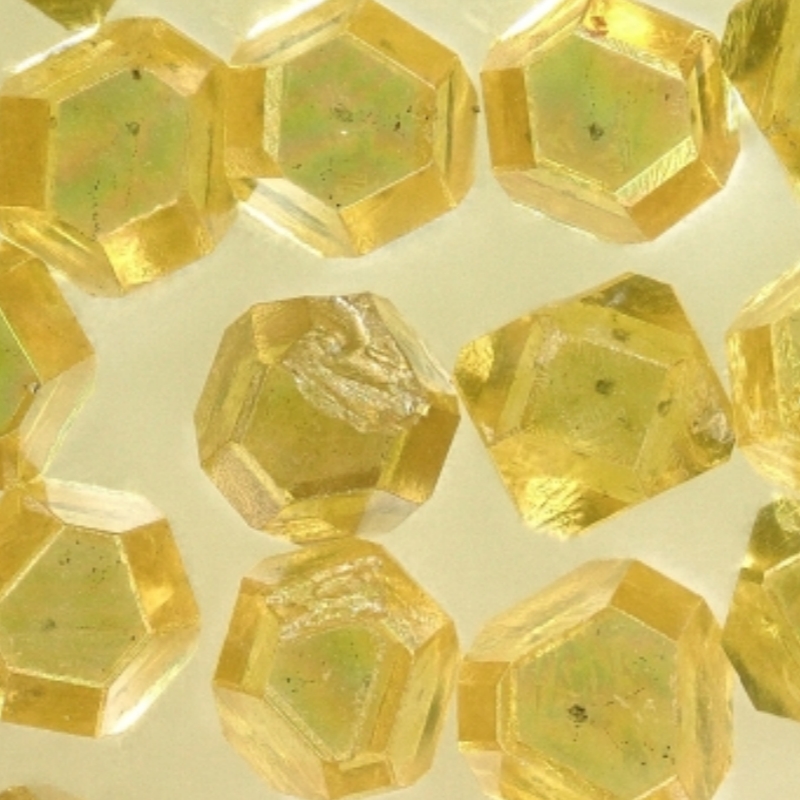

High purity diamond material (WBD2160) is an advanced synthetic diamond designed for precision applications requiring superior hardness, chemical stability, and thermal conductivity. Manufactured through high-pressure high-temperature (HPHT) or chemical vapor deposition (CVD) methods, this material exhibits exceptional purity and minimal inclusions, making it ideal for high-performance cutting, semiconductor substrates, optical components, and electronic thermal management systems. Its ultra-durable properties ensure extended operational lifespan and optimized efficiency in demanding industrial applications.

Product Overview

WBD2180 is a diamond material with high impact resistance and excellent thermal stability. It features high transparency and complete crystal form, making it ideal for high-end cutting, drilling, and grinding tools. Its outstanding performance ensures superior results under high-load conditions, especially in environments that demand high strength and stability.

Features

- Complete Crystal Structure: Ensures efficiency and stability during cutting and grinding processes.

- High Transparency: Excellent transparency allows for high-precision cutting and grinding results.

- High Impact Resistance: Exceptional impact strength, making it ideal for high-load and high-impact environments.

- Good Thermal Stability: With excellent thermal stability, it can withstand high-temperature working conditions.

Applications

- High-End Cutting Tools: Suitable for efficient cutting of materials such as ceramics and reinforced concrete, ensuring precision and durability.

- Drill Bits: Ideal for various drilling tools, especially for drilling under high-impact loads.

- Grinding Tools: Widely used in high-precision grinding tools, providing excellent grinding performance and longer service life.

new material

new material