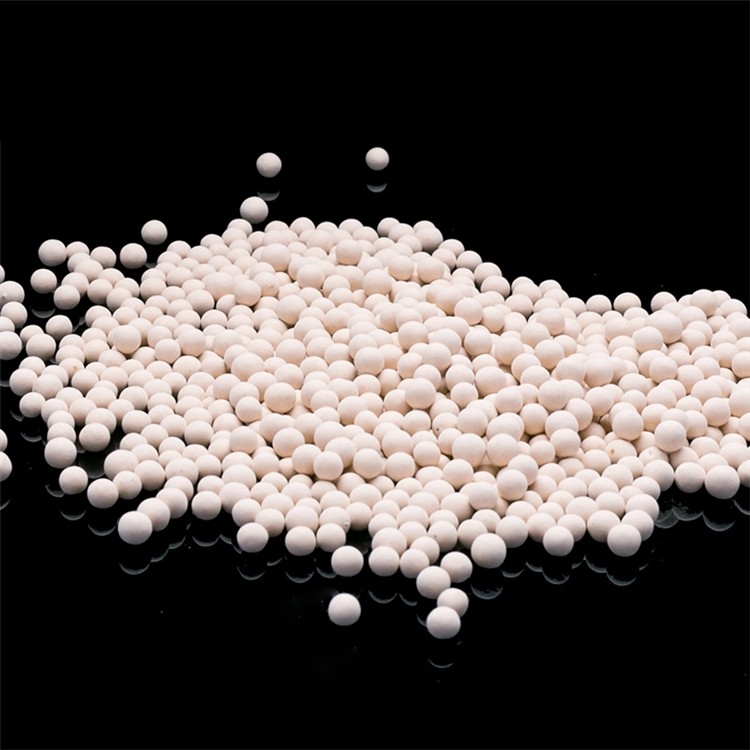

ReY series molecular sieve is a high-performance rare earth-modified zeolite designed for advanced catalytic applications and selective adsorption processes. Featuring an optimized pore structure with enhanced thermal stability and acidity, it provides superior efficiency in hydrocarbon conversion, petrochemical refining, and industrial gas purification. This molecular sieve is widely used in fluid catalytic cracking (FCC), selective catalytic processes, and large-scale hydrocarbon processing, delivering reliable performance for continuous industrial operations.

Product Overview

The ReY Series Molecular Sieve is a high-performance catalyst support material that utilizes a unique rare earth element treatment technology to enhance the activity and stability of the sieve. This molecular sieve is particularly suited for petroleum refining and chemical reactions, where it significantly improves catalytic reaction rates and selectivity, optimizing the production process. With its robust structure and favorable pore characteristics, the ReY series molecular sieve is ideal for use under extreme conditions such as high temperature and high pressure. It is widely applied in industries such as petrochemicals and coal chemicals.

Key Features

- High Activity: The addition of rare earth elements enhances the catalytic performance of the sieve, making it suitable for a wider range of reaction conditions.

- High Stability: Exhibits excellent thermal stability and resistance to poisoning, maintaining strong performance under high temperature and high pressure conditions.

- Selective Adsorption: The well-designed pore structure allows selective adsorption based on molecular size, improving separation efficiency.

- High Surface Area: Offers a larger number of adsorption sites, enhancing the efficiency of catalytic reactions and improving product yields.

Applications

- Petroleum Refining: Used in processes such as catalytic cracking, hydrocracking, and reforming to improve the quality and yield of petroleum products.

- Chemical Reactions: Widely used in chemical production to increase reaction rates and selectivity while reducing energy consumption.

- Coal Chemical Industry: Applied in catalytic reactions in coal gasification, coal-to-liquid processes, and other coal chemical applications, enhancing efficiency and selectivity.

- Environmental Protection: Used in catalytic processes for waste gas treatment to reduce harmful emissions and improve environmental quality.

| Technical Specification | ReY2.0 | ReY8.0 | LaY | CeY16 |

| Shape | Powder | Powder | Powder | Powder |

| Cation Type | Re | Re | Re | Re |

| SiO₂/Al₂O₃ (mol/mol) | 5.6 | 5.8 | 5.4 | 5.4 |

| SiO₂ (%) | / | / | / | / |

| Al₂O₃ (%) | / | / | / | / |

| Re₂O₃ (m/m %) | 2.1 | 8.2 | 16.5 | 18 |

| Na₂O (m/m %) | 1.1 | 0.95 | 1.1 | 1.2 |

| Unit Cell Size | 24.56 | 24.68 | 24.69 | 24.66 |

| Crystallinity | 68 | 54 | / | 68 |

| Surface Area (m²/g) | 640 | 630 | 620 | 610 |

| Micro PV (cc/g) | / | / | / | / |

| Pore Size | / | / | / | / |

| Bulk Density (g/ml) | / | / | / | / |

| LOI (m/m %) | 17 | 22 | 17.9 | 18 |

| D50/D90 | 4~8 | 4~8 | 4~8 | 4~8 |

| Crystal Size | / | / | / | / |

| N-Hexane Adsorption (m/m %) | / | / | / | / |

new material

new material