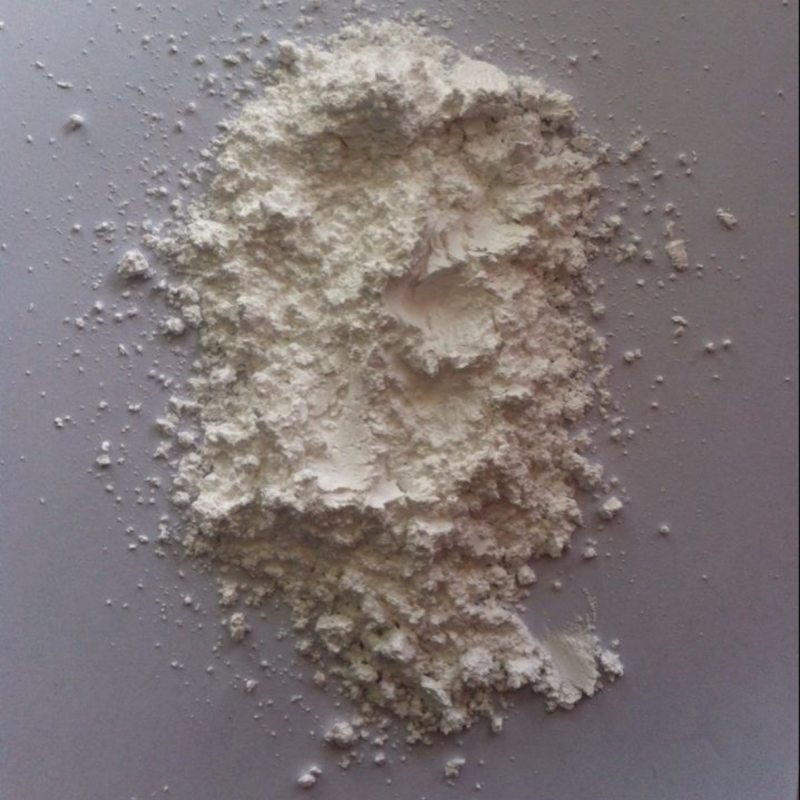

NaY molecular sieve is a high-performance synthetic zeolite designed for efficient gas separation, adsorption, and catalytic applications in industrial processes. Featuring a well-defined pore structure and superior ion-exchange capacity, it selectively removes impurities such as CO₂ and moisture from gas streams while enhancing catalytic activity. This molecular sieve is widely used in petrochemical refining, air separation, hydrogen purification, and large-scale hydrocarbon conversion, delivering reliable adsorption and catalytic efficiency for continuous industrial operations.

Overview

NaY molecular sieve features a unique eight-faced zeolite cage structure. Compared to A-type and X-type molecular sieves, NaY has a higher silicon-to-aluminum ratio and larger pore size, offering superior selectivity, adsorption activity, thermal stability, and acid resistance. NaY molecular sieve is widely used in petroleum refining, natural gas treatment, and as a catalyst support, providing enhanced stability and efficiency for various processes.

Key Features

- Excellent Selectivity and Adsorption Activity:With a higher silicon-to-aluminum ratio and larger pore size, NaY molecular sieve exhibits stronger adsorption capacity and higher selectivity than A-type and X-type sieves.

- Strong Thermal Stability:With good thermal stability, it is suitable for high-temperature applications.

- Superior Acid Resistance:NaY offers better acid resistance compared to other molecular sieves, making it suitable for a wider range of applications.

- Optimized for Catalytic Reactions:Provides higher efficiency and stability in catalytic processes, especially in the petroleum and chemical industries.

Applications

- Petroleum Refining:Used as a catalyst support in petroleum refining processes, improving reaction efficiency.

- Natural Gas Treatment:Applied as an adsorbent for impurity removal in natural gas purification and separation.

- Catalyst Optimization:Enhances the performance of various catalytic reactions, extending catalyst life and improving results.

- Gas Separation:Used for gas separation and purification, particularly in environments that require efficient adsorption.

| Parameter Name | Test Result |

| Relative Crystallinity | 92% |

| Unit Cell Constant | 24.65 × 10⁻¹⁰ m |

| Silica-to-Alumina Ratio | 5.2 |

| Sodium Oxide Content | 11.80% |

| BET Specific Surface Area | 715 m²/g |

| Average Loss on Ignition | 22.48% |

new material

new material