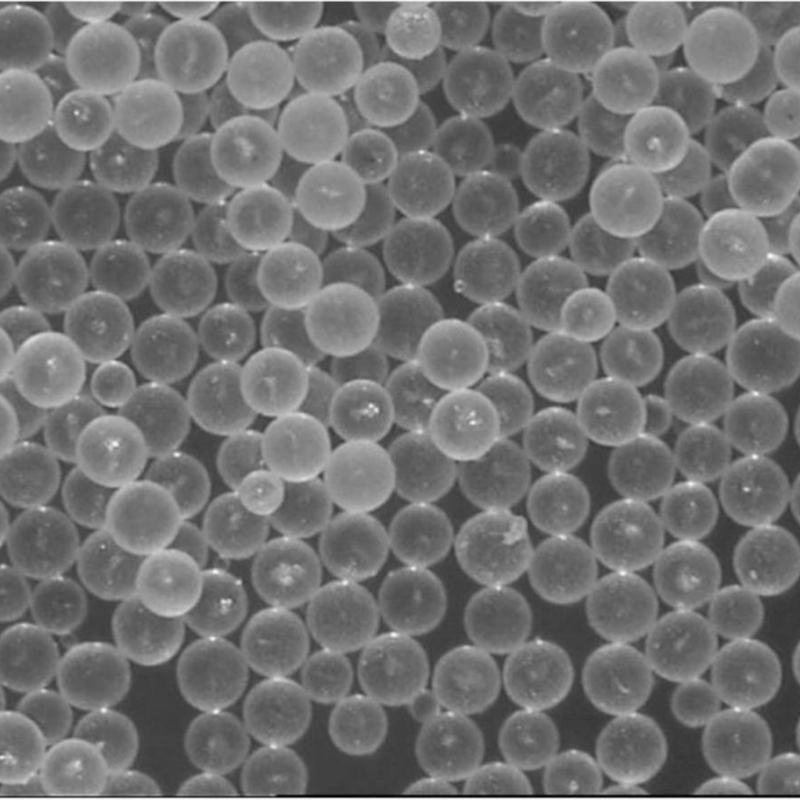

Silica gel support for olefin polymerization catalysts is a high-performance material engineered to provide excellent dispersion, stability, and active site accessibility for catalytic polymerization processes. Designed with optimized pore structure and surface properties, it enhances catalyst efficiency, ensures uniform polymer formation, and improves reaction kinetics in industrial applications. This support is widely used in polyolefin production, petrochemical refining, and advanced polymer synthesis, delivering reliable performance for continuous polymerization processes.

Product Overview

This product is made from sodium silicate and sulfuric acid through a unique purification process, resulting in high chemical purity, narrow particle size distribution, and suitable pore size distribution. After years of industrial application verification, catalysts made with this silica gel support show stable performance, good fluidization behavior, and are particularly well-suited for fluidized bed catalysts.

Key Features

- High Purity:Silica content exceeds 99.3%, ensuring the catalyst support has high purity.

- Excellent Pore Structure:Features a suitable pore size distribution and good pore volume, providing ideal support for catalytic reactions.

- Good Fluidization:The silica gel support exhibits excellent fluidization behavior during catalyst preparation, enhancing catalytic efficiency.

- Stable Catalytic Performance:Catalysts prepared using this silica gel support offer stable performance, making them suitable for long-term industrial use.

Applications

- Olefin Polymerization Catalyst Support:Especially suitable for gas-phase polyethylene polymerization catalysts, providing ideal catalytic support.

- Fluidized Bed Catalysis:This silica gel support shows excellent fluidization properties and stability in fluidized bed reactions.

- Petrochemical Catalysts:Widely used in the preparation of various polymerization catalysts in the petrochemical industry.

| Property | Specification |

| Silica Content (dry basis) %≥ | ≥99.3 |

| Loss on Heating (%) | ≤5.0 |

| Loss on Ignition (%) | ≤6.0 |

| Total Calcium and Magnesium (as Ca) % | ≤0.3 |

| Ferric Oxide (Fe₂O₃) % | ≤0.05 |

| Sodium Oxide (Na₂O) % | ≤0.15 |

| Tapped Density (g/ml) | 0.28-0.32 |

| Pore Volume (g/ml) | 1.6~1.9 |

| Surface Area (m²/g) | 280~350 |

| Oil Absorption (ml/g) | 2.5~3.5 |

| Average Particle Size (μm) | 36~45 |

new material

new material