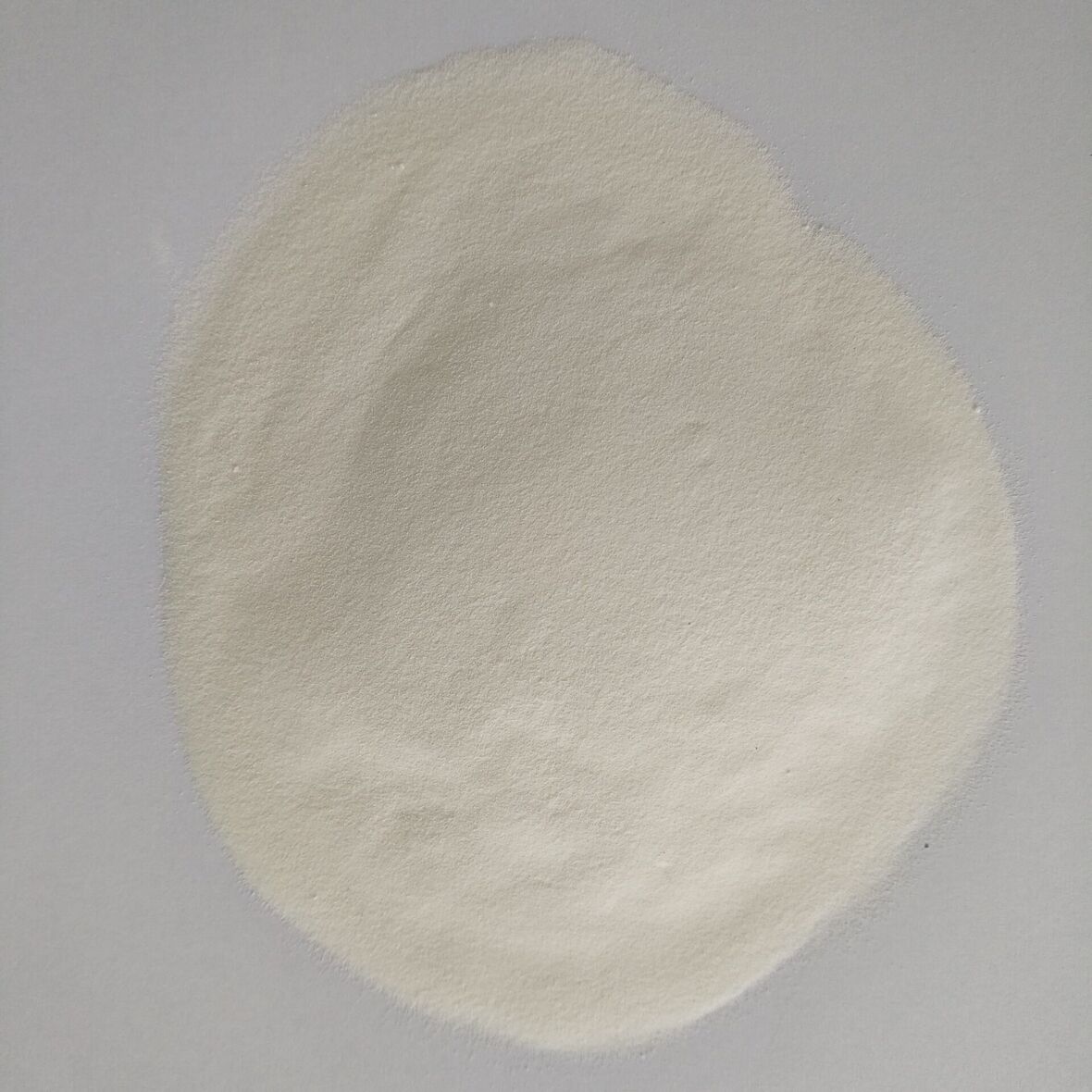

Platinum-based carbon monoxide combustion aid is an advanced catalytic material engineered to enhance the oxidation of carbon monoxide (CO) into carbon dioxide (CO₂), ensuring superior efficiency and stability. Designed with optimized platinum formulations, it promotes rapid catalytic reaction kinetics, improves combustion performance, and extends operational lifespan for industrial applications. This catalyst is widely used in emissions control, automotive exhaust purification, and industrial air treatment, delivering reliable performance for continuous CO oxidation.

Product Overview

The platinum-based carbon monoxide combustion aid is specifically designed for catalytic cracking units in refineries to improve energy efficiency and catalyst regeneration. Its primary function is to convert carbon monoxide (CO) generated in the regenerator into carbon dioxide (CO₂), reducing the carbon content of the regenerator, maintaining catalyst activity, enhancing catalyst regeneration, and recovering reaction heat. This product has significant economic and environmental benefits, including energy conservation, stable operation, increased light oil yield, and reduced environmental pollution.

Key Features

- High Efficiency: Platinum-based catalysts are highly active and effectively promote the conversion of carbon monoxide to carbon dioxide, reducing operational costs.

- Energy Saving & Environmental Protection: By recovering reaction heat, it lowers energy consumption and reduces harmful gas emissions, contributing to environmental protection.

- Excellent Stability: Strict quality control ensures long-term stability and high efficiency of the product.

- Low Usage & Cost-Effective: The high platinum content provides excellent activity, reducing the actual amount needed and lowering overall costs.

- Diverse Varieties: Multiple specifications are available to meet the needs of different types of catalytic cracking units, with support for customized product development.

Applications

- Catalytic Cracking Units: Used in refinery catalytic cracking processes to enhance catalyst regeneration, recover reaction heat, and improve operational efficiency.

- Energy Saving: By lowering the generation and conversion of carbon monoxide, it enhances overall energy efficiency and reduces energy consumption.

- Petrochemical Industry: Widely used in petroleum, natural gas processing, and chemical engineering to improve the economic efficiency and environmental friendliness of cracking processes.

- Environmental Protection & Energy Conservation: Reduces carbon monoxide emissions, mitigating environmental pollution and offering sustainable development solutions for enterprises.

| Property Name | Grade 1 | Grade 2 | Grade 3 | Grade 5 | Test Method | |

| Platinum Content (ppm) | 100 | 200 | 300 | 500 | Spectrophotometric | |

| Al₂O₃ (%)(m/m) | 98 | 98 | 98 | 98 | GB/T 6609 | |

| Na₂O (%)(m/m) | ≤0.55 | ≤0.55 | ≤0.55 | ≤0.55 | GB/T 6609.5 | |

| Fe₂O₃ (%)(m/m) | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | GB/T 6609.4 | |

| Specific Surface Area (m²/g) | ≥50 | ≥50 | ≥50 | ≥50 | BET Static Adsorption Method | |

| Pore Volume (ml/g) | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | BET Static Adsorption Method | |

| Particle Size Distribution (%)(m/m) | - <40μm (max) | 30 | 30 | 30 | 30 | |

| - 40-80μm (min) | 40 | 40 | 40 | 40 | ||

| - >80μm (max) | 30 | 30 | 30 | 30 | ||

| CO Relative Conversion Rate (%) | ≥90 | ≥90 | ≥90 | ≥90 | ||

new material

new material