Furaldehyde hydrogenation catalyst for 2-methylfuran production is a high-performance catalytic material designed for the selective hydrogenation of furaldehyde into 2-methylfuran with superior conversion efficiency and stability. Engineered using optimized metal-supported formulations, it enhances reaction kinetics, improves hydrogenation selectivity, and ensures prolonged operational lifespan for industrial applications. This catalyst is widely used in fine chemical synthesis, pharmaceutical intermediate manufacturing, and biomass-derived compound processing, delivering reliable performance for continuous catalytic hydrogenation.

Product Overview

This catalyst is a multimetal-modified copper catalyst specifically designed for the hydrogenation of furaldehyde to produce 2-methylfuran. It exhibits an exceptionally high furaldehyde conversion rate of ≥99.5% and outstanding selectivity for 2-methylfuran, achieving ≥90% selectivity, which is 1 to 3 percentage points higher than conventional industrial catalysts. Additionally, the catalyst offers a long service life of at least 3 months, significantly enhancing the economic benefits of production.

Key Features

- High Conversion Rate: Furaldehyde conversion rate ≥99.5%, ensuring highly efficient reactions.

- High Selectivity: 2-Methylfuran selectivity ≥90%, enhancing product purity and quality.

- Long Service Life: Catalyst life ≥3 months, reducing the frequency of catalyst replacement and associated costs.

- High Overall Economic Benefit: Provides higher economic returns compared to existing industrial catalysts, making it suitable for large-scale industrial applications.

Applications

- Furaldehyde Hydrogenation for 2-Methylfuran Production: Primarily used in the hydrogenation of furaldehyde for industrial production of 2-methylfuran.

- Fine Chemical Production: Can also be used in hydrogenation reactions for other chemicals, improving yield and product quality.

- Green Chemistry Industry: Offers catalytic solutions for low-energy, high-efficiency production, aligning with sustainable development goals in modern chemical industries.

| Catalyst Technical Specifications | |

| Item | Technical Specification |

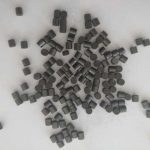

| Appearance | Black cylindrical φ5×4~5mm |

| Strength (N/cm) | >150 |

| Bulk Density (g/L) | 1400~1700 |

| Surface Area (m²/g) | 50~80 |

| Pore Volume (ml/g) | 0.1~0.3 |

| Water Content (%) ≤ | 2 |

| Item | Technical Specification |

| Reaction Temperature (℃) | 160~230 |

| Reaction Pressure (MPa) | 0.01~0.1 |

| Liquid Space Velocity (h⁻¹) | 0.08~0.12 |

| H₂/CH₂O Molar Ratio | 6~20:1 |

new material

new material