Dry gas ethylbenzene catalyst is a high-performance catalytic material designed to facilitate the selective transformation of ethylbenzene in dry gas environments with superior efficiency. Engineered using advanced metal-supported or zeolite-based catalysts, it ensures optimized reaction kinetics, enhanced yield, and prolonged operational stability in controlled petrochemical refining processes. This catalyst is widely used in ethylbenzene conversion, industrial aromatic hydrocarbon processing, and fine chemical synthesis, providing reliable performance for large-scale applications requiring precision catalytic control.

Product Overview

The dry gas ethylbenzene catalyst is designed for the industrial synthesis of ethylbenzene, offering excellent sulfur resistance and hydrothermal stability. This catalyst allows the direct use of raw gas from catalytic cracking without the need for additional treatment. Compared to using pure ethylene as the raw material, it offers the same performance at a significantly lower cost, improving production efficiency and reducing operational costs. The catalyst has been successfully applied in several industrial plants, delivering substantial economic benefits.

Key Features

- Strong Sulfur Resistance: The catalyst has excellent sulfur tolerance, ensuring stable operation even in sulfur-containing gas environments.

- Good Hydrothermal Stability: It can withstand high temperatures and steam environments, ensuring stability under harsh conditions.

- Outstanding Economic Benefits: The catalyst allows for ethylbenzene production using catalytic cracking gas, which requires no additional processing, offering significant cost savings and economic benefits.

- Wide Application: Successfully applied in multiple industrial plants, demonstrating high reliability and excellent performance.

Applications

- Ethylbenzene Synthesis: Mainly used for direct ethylbenzene synthesis from dry gas or catalytic cracking raw gas, widely applied in the chemical and petrochemical industries.

- Petrochemical Industry: Can be used to directly convert gases from petroleum cracking into ethylbenzene, providing an effective way to lower production costs and improve profitability.

- Cost-Effective Catalytic Applications: Ideal for ethylbenzene production plants that need to reduce costs while maintaining high yields.

| Property | Value |

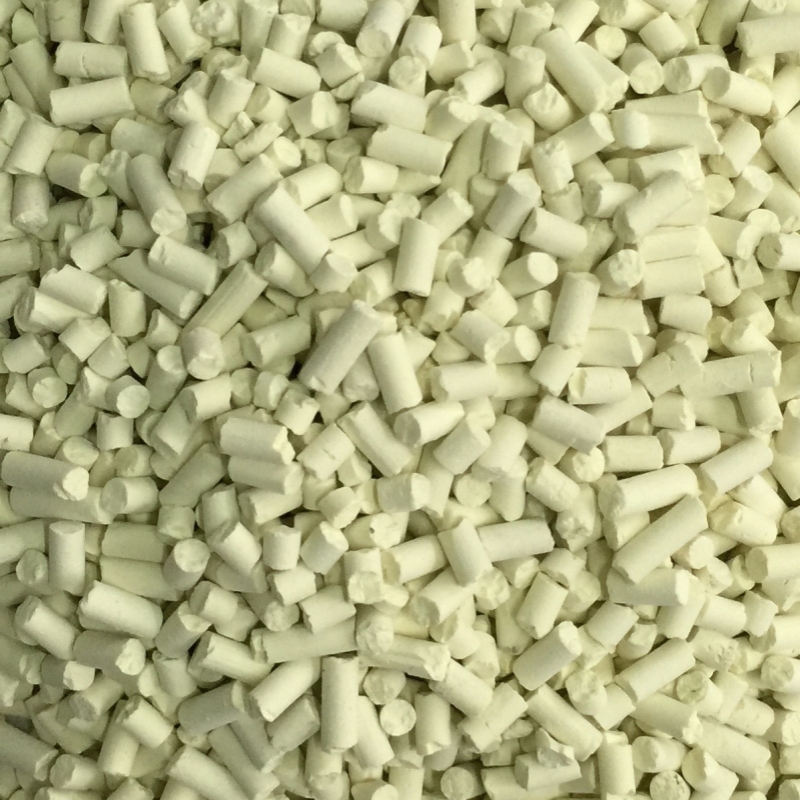

| Chemical Composition | La-ZSM-5-Al2O3 |

| Shape | Rod-shaped |

| Size (mm) | Φ1.8×3~8 |

| Bulk Density (g/ml) | 0.6~0.7 |

| Crushing Strength (N/mm) | ≥9.8 |

new material

new material